|

|

| Model | CAP-300 Series Reliable Coolant Level Sensor | | Description | The CAP-300 capacitive level sensor is one of our most durable and reliable point level sensors. Compatible with coolants, the CAP-300 is the ideal OEM solution for power generation equipment, off-highway vehicles and cell phone tower generators and can be mounted in any position. With nearly zero maintenance, the sensor is small in size, tolerates coating and will remain reliable even in the standby mode. Compatible with temperatures up to 257°F (125°C) the capacitive based sensor is suited for the most challenging environments. Available with a variety of mounting types and electrical connections, the CAP-300 is the ideal solution for coolant monitoring.

> Durable sealed design – IP67, IP6K9K

> Developed for the most rugged coolant applications

> Tolerates coolant coating

> Small size – 2˝ (51 mm) long

| | Maker | Gems Sensors | | Category | Level Switch | | Highlights | | | Applications | | | Industry | Coolant Level | | Keywords | | | Product Image |  | | Model | 3D Level Scanner | | Description | 3D Level Scanning – A Multipoint Level Solution

Bindicator has partnered with APM Solutions to bring the 3DLevelScanner to market. The 3DLevelScanner Model S determines the average volume of bulk solids stored in small silos with diameters of up to 13 feet (4 m). It incorporates a non-contact dust-penetrating technology enabling it to overcome the challenges of harsh, dusty environments in many applications.

How It Works

The 3DLevelScanner employs an array of antennas to transmit low frequency pulses and to receive echoes of the pulses from the contents of the silo, bin, and other containers. The unit measures the time/distance of each echo and its direction. The device’s Digital Signal Processor samples and analyzes the received signals to provide very accurate measurements of the level and volume of the stored contents. | | Maker | Bindicator | | Category | 3D Level Scanner | | Highlights | | | Applications | | | Industry | volume of bulk solids | | Keywords | | | Product Image |  | | Model | Pulse Point™ II Series | | Description | Simplicity At Its Best With Consistent Results

The Pulse Point™ II Series is a simple mechanical device that is flexible enough to fit into almost any bulk solid application. The Pulse Point II uses electronic vibratory technology to sense the presence or absence of material. Voltage is applied to the fork, which causes it to vibrate; when material comes into contact with the fork, the vibration stops and a signal is produced.

Integral units combine the sensing fork and electronics into one unit, while a remote option separates the fork from the electronics. With a maximum distance of 100 ft (30 m), the remote option is often used for higher temperature applications or when the location of the electronics needs to be more convenient. | | Maker | Bindicator | | Category | Tuning Fork | | Highlights | | | Applications | | | Industry | Point Level Sensors | | Keywords | | | Product Image |  | | Model | Roto-Bin-Dicator | | Description | Roto-Bin-Dicator, Versatility At Its Best

The Roto-Bin-Dicator is the most universal of all level sensing technologies and is the most popular level switch used in dry bulk materials. The Roto-Bin-Dicator is a rotating paddle type, bulk material level sensor offered in a wide variety of paddle options for unequaled application versatility. It is easy to install and requires no special tools or calibration.

Bindicator offers the Original Roto-Bin-Dicator models for Low Level Fail Safe protection, Super-Safe-Plus models for High Level Fail Safe requirements, and Mini-Roto for tight spaces. | | Maker | Bindicator | | Category | Rotary Level Sensor | | Highlights | | | Applications | | | Industry | Point Level Sensors | | Keywords | | | Product Image |  | | Model | The VRF® II Level Sensor | | Description | Surpassing sensitivity for the toughest applications

The VRF® II Series is one of the most versatile radio frequency units on the market. The VRF is able to detect the presence or absence of material by calibrating itself to air then alarms when there is a change. Because the unit can automatically determine its optimal frequency, it is ideal for tough, sensitive environments and materials.

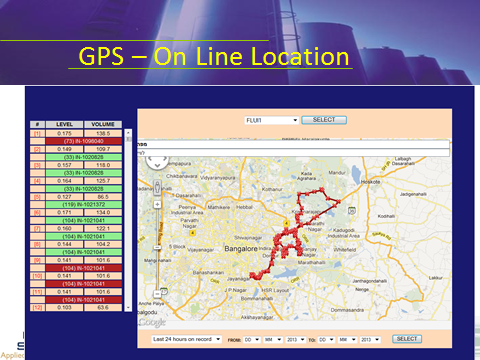

Integral units combine the sensing probe and electronics into one unit, while a remote option separates the probe from the electronics. With a maximum distance of 100 ft (30 m), the remote option is often used for higher temperature applications or when the location of the electronics needs to be more convenient. | | Maker | Bindicator | | Category | Radio Frequency | | Highlights | | | Applications | Point Level Sensors | | Industry | Point Level Sensors | | Keywords | | | Product Image |  | | Model | GaugerGPS | | Description | GaugerGPS is a solution for "sensing-in-motion". A typical application is the monitoring of diesel tanks on vehicular tankers. In this application GaugerGPS transmits periodic reports including LEVEL and VOLUME (liters/Gallons), temperature, LOCATION, power supply status and cellular signal strength. In addition, GaugerGPS transmits immediate reports for alerting events.

HIGHLIGHTS and BENEFITS

Improve your productivity and lower your costs of fuel dispensing operations.

Identify and prevent costly illegitimate activities.

Visibility of your operations.

Where are the tanker vehicles? When did they depart in the morning?

Is a tanker at an authentic dispensing site?

How much fuel is being dispensed?

| | Maker | Solid Applied Tech | | Category | Ultrasonic Level | | Highlights | | | Applications | | | Industry | Tank Level Monitoring | | Keywords | | | Product Image |  | | Model | GaugerNET | | Description | GAUGER MONITOR is a remote monitoring application for viewing data from fielded GaugerGSM sensors. The application provides for graphic and table views of data. | | Maker | Solid Applied Tech | | Category | Ultrasonic Level | | Highlights | | | Applications | | | Industry | Tank Level Monitoring | | Keywords | | | Product Image |  | | Model | Gauger485 | | Description | WATER MONITORING

are solutions for monitoring level in flowing rivers, irrigation channels, water reservoirs and water tanks. Applications span ranges as small as 40cm (1') and all the way up to 40m (130') typical for dam installations. The level sensors can be set to calculate open channel flow or report flooding / dryout conditions. The sensors are non-contact and based on ultrasonic technology which is the technology of choice for water applications whether smooth surface or wavy and turbulent. | | Maker | Solid Applied Tech | | Category | Ultrasonic Level | | Highlights | | | Applications | | | Industry | Tank Level Monitoring | | Keywords | | | Product Image |  | | Model | GaugerGSM | | Description | SEWER LEVEL MONITORING

The sewer level monitoring solution is based GaugerGSM level sensor and GaugerNET, a web-based monitoring application. The fielded component includes the sesnor, external battery pack and a programmable time switch. The complete set may be provided Intrinsic Safe (ATEX and IECEx). This solution is perfect for detecting overflow conditions, quantifying sewer flows, identifying long-term sewage trends and meeting regulatory requirements. | | Maker | Solid Applied Tech | | Category | Ultrasonic Level | | Highlights | | | Applications | | | Industry | Tank Level Monitoring | | Keywords | | | Product Image |  | | Model | Gauger420 | | Description | GAUGER PRODUCT LINE

consists of state-of-the-art compact level sensors, rugged and fitting a wide range of applications. GaugerGSM stands out as a level sensor for remote monitoring applications featuring GSM (GPRS/SMS) cellular communications. Gauger420 is two-wire level sensor for industrial application with rapid process tracking rate, sealing rated IP68 and PVDF sensor for use with aggressive chemicals. Gauger420 supports 4-20mA and optional HART. Both Gauger models are available Intrinsic Safe ATEX / IECEx. | | Maker | Solid Applied Tech | | Category | Ultrasonic Level | | Highlights | | | Applications | | | Industry | Tank Level Monitoring | | Keywords | | | Product Image |  |

|

|