Single-pole (Magnet) System

Single-pole (Magnet) SystemThe WEKA Magnetic Level Indicator operating principle is based on the use of a permanent bar magnet system which ensures the safe and reliable activation of visual indication elements (flags), switches and transmitters, even when used on thick-wall high-pressure indicator pipe. Magnetic Guide Tape (patented) The patented magnetic guide tape is integrated within the indicator rail to ensure the float bar magnet is always aligned like a compass needle to the polarized flags and switches. This ensures continuous reliability of the indicating, switching and transmitter control functions. Temperature Stability The magnetic materials used in the WEKA System have been selected for optimum performance even at extreme temperatures. Years of experience have proven our preconditioning of components ensures negligible degradation of magnetic flux, thus providing the same reliable service decades later. Magnetic Coupling Every flag of the WEKA indication rail is equipped with its own permanent magnet. Thus the indication flags magnetically interlock with each other and so are kept in a stable position. The patented guide tape further enhances performance through the magnetic damping effect that produces safe and reliable indication of liquid level, even under difficult applications with rapidly changing liquid levels or vibrations. Compact Design The low weight of the WEKA bar magnet permits the use of lightweight hermetically sealed floats. Compact in size, the WEKA floats ensure the highest possible diameter difference between float OD and tube ID - an important advantage when dirty or highly viscous liquids need to be measured. The short float design also often enables a larger indication than competitive products. . |

||||||||||||

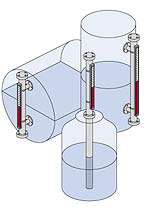

WEKA Visual Level Indicators: three instruments in one!

WEKA Visual Level Indicators: three instruments in one!

Wide Application Range Operating pressures from vacuum to ISO PN420 (cl2500) - standpipes up to PN630 - are possible. Liquid densities as low as 300 kg/dm 3 (SG 0.3) and an operational temperature range from 77 K to 673 K (-196 to 400? C) allow use with cryogenic liquids as well as steam boilers or water hydraulics. Hermetically sealed, non-pressurized floats for condensing media are available up to 320 bar operating pressure. . |

||||||||||||

Flexibility through Choice of Materials

Interfaces to Process Control An upgrade from a Level Indicator to a Level Controller can easily be accomplished by adding WEKA Magnetic Switches. The switch point can easily be adjusted to changing process conditions. Switches in SPST or SPDT, EEx ib, EEx ia or EEx d versions. Polycarbonat or SS housings IP 68/IP 67. Switch rating: 220/60 VA for AC, 160/40 W for DC. Up to 400? C media temperature. Transmitters are used to upgrade an existing Level Indicator to a Level Transmitter. Available in standard 3-wire or 2-wire 4?0 mA version, CENELEC EEx ia II C T3 or EEx d IIC T6. Standard resolution 10 mm, 5 mm optional. Up to max. 350?C media temperature. Safety The liquid is confined to the tight, pressureated standpipe with the indicator rail outside, thus separated from the media. Damage to the indicator is unlikely to cause the immediate leakage that could be the case with other visual indicator types. Energy-free Operation WEKA Magnetic Level Indicators are ideally suited for systems start-up. The visual indication operates absolutely energy-free and simply follows the principle of communicating vessels. Independent from the process controller, a WEKA Magnetic Level Indicator provides an on-the-spot visual readout ?even during system failure or mains power loss. . |

||||||||||||

Perfect Readability

Perfect ReadabilityThe wide, contrasting indication rail assures easy visibility, even at great distances. The all-around transparent Polycarbonat indication rail also permits readability from the side. Aluminum and SS indicator rails also have the same wide view but are designed for more hostile environments and higher temperatures. In corrosive atmospheres the indicator rails can be hermetically sealed without restricting the visibility. The safe and easy reading of the liquid level is not impaired by product contamination, clouding or protective shields. Level Measurement ?la carte WEKA stands at the forefront of Magnetic Level Indicator state of the art for almost any operating conditions. Most of the applications can be served with one of our standard instruments. For special applications we invite you to draw from our wealth of more than 40 years experience in the design and manufacture of Magnetic Level Indicators installed all over the world in extremes of environments and applications. No matter how complex your requirements are, the patented and field-proven WEKA magnetic float indication rail system will meet your liquid level indication requirements. |

For more info, contact sales@isensors.com.sg